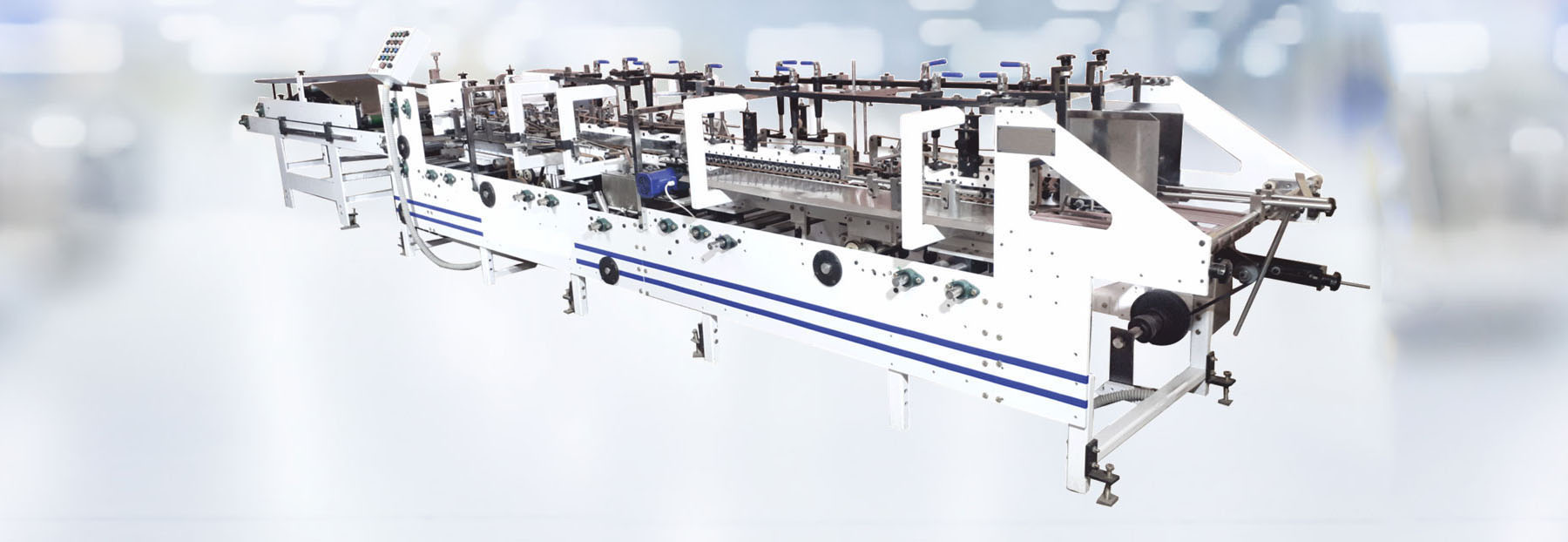

Eco Fold Carton Folder Gluer

FOLDER GLUER FOR CRASH LOCK BOTTOM CARTONS RIGID & ECONOMICAL MACHINE WHICH CAB HANDLE DUPLEX AS WELL AS TRIPLY CARTONS FOR STRAIGHT LINE & LOCK BOTTOM CARTONS.

SALIENT FEATURES

- Variable speed with clutch in Feeder

- 130 & 180 Pre-Fold

- 3 Bottom Track & 5 Top Tracks

- Lockable top track holder handles

- High speed lock hooks

- Individual speed variable final folding belts

- A&B pin separate glue tank (Fully stainless steel)

- Gum flap Grinder

- Batch counter with pneumatic kicker

- VFD, PLC SYNC, HMI & push button operated panel

- Mechanical pressured pressing station (extended if required)

- Separate motor for Pressing station

- Compactable for duplex, met-pet, triply cartons

- CNC machined & powder coated solid frame

- Anti vibration padded legs

- All hardchrome alloy shafts

- Complete hardened bolts

- 3 Nozzle electronic gluing system with touch screen control

OPTIONAL FEATURES

- Plasma curing system

- Quality assurance system

- Braille embossing system

- Clapping device for corrugated cartons

- Cache cover attachment

- Flip top carton attachment

- Double wall carton attachment

- Tube light carton attachment

Feeder

Variable speed driven: The feeding unit with variable drive is designed to allow appropriate space between the cartons.

Electro magnetic feeder clutch system is to stop the feeder unit while the entire machine is running.

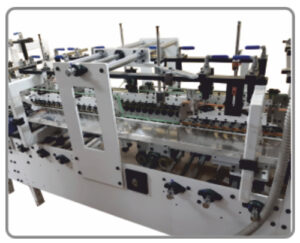

PRE -FOLDING OR CRASH LOCK BOTTOM UNIT

The first and third crease can be pre-folded at 180 & 135 respectively.

For folding of all lock bottom flaps this unit is designed in three transport tracks in 2 units, so that the carton remains under pressure of all three tracks at the time of folding of flaps for lock bottom & four/six corner boxes.

This prevents shifting or non alignment of cartons resulting to low wastage and increases production speed.

Self adjustable transport tracks for duplex and E-flute cartons.

FINAL FOLDING UNIT WITH SPEED VARIATOR

The folding of second and fourth crease after gluing process.

The highly performing design of folding belts & runner which plays a vital role in final finishing at a high speed.

Variable speed of final folding belts.

The side lay belt speed can be varied by speed variator knob.

Optional collapsable centre bottom track.

TRANSFER SECTION

It allows the carton to be transferred to pressure unit in regular, constant flow at any production speed.

Equipped with push button control for the operating of the machine.

Batch counter equipped with electronic sensor and pneumatic kicker.

Optional Straitening device used to correct the registration of outer cartons.

Optional clapping device used for corrugated cartons.

PRESSURE DELIVERY

3.7mtr length with 2.5 mtr length effective pressing station.

Separate motor for pressing station. The independent geared motor helps in increasing or decreasing the speed of unit. So that the different size (Duplex or Triply) of cartons comes between the pressure belts smoothly.

The finished carton comes under a pressure rollers & get cured.

Technical Specification of Machine |

|||

Models |

Power Required | Dimension |

Max. Speed |

VEENINE 65 |

8 KW | 1.2 mtr X 8.6 mtr |

200 mtr/m |

| VEENINE 80 | 10 KW | 1.4 mtr X 9 mtr |

200 mtr/m |

| VEENINE 100 | 12 KW | 1.6 mtr X 9.5 mtr |

200 mtr/m |

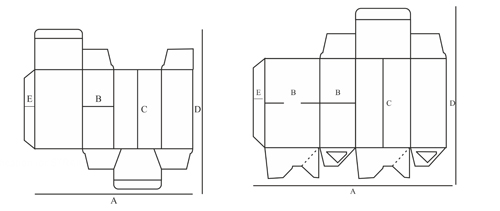

Technical Specification for STRAIGHT LINE CARTONS |

|||||||

Models |

A min. |

A max. |

B Min. |

B Max. |

C Min. |

D Max. |

E Min. |

VEENINE 65 |

60 mm |

650 mm |

15 mm |

250 mm |

55 mm |

450 mm |

11 mm |

| VEENINE 80 | 110 mm |

800 mm |

25 mm |

300 mm |

80 mm |

550 mm |

12 mm |

| VEENINE 102 | 140 mm |

1020 mm |

30 mm |

400 mm |

120 mm |

700 mm |

12mm |

|

Technical Specification for LOCK BOTTOM CARTONS |

||||||

Models |

A min. |

A max. |

B Min. |

C Min. |

D Max. |

E Min. |

VEENINE 65 |

140 mm |

650 mm |

32 mm |

90 mm |

450 mm |

11 mm |

| VEENINE 80 | 140 mm |

800 mm |

32 mm |

130 mm |

550 mm |

12 mm |

| VEENINE 102 | 160 mm |

1020 mm |

50 mm |

150 mm |

700 mm |

12mm |